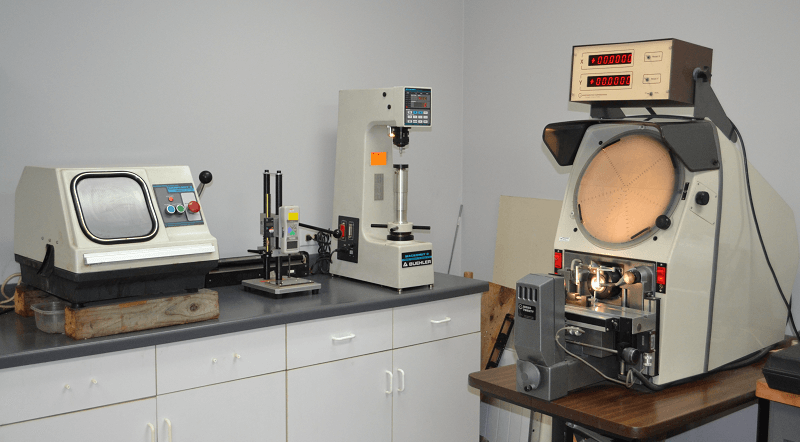

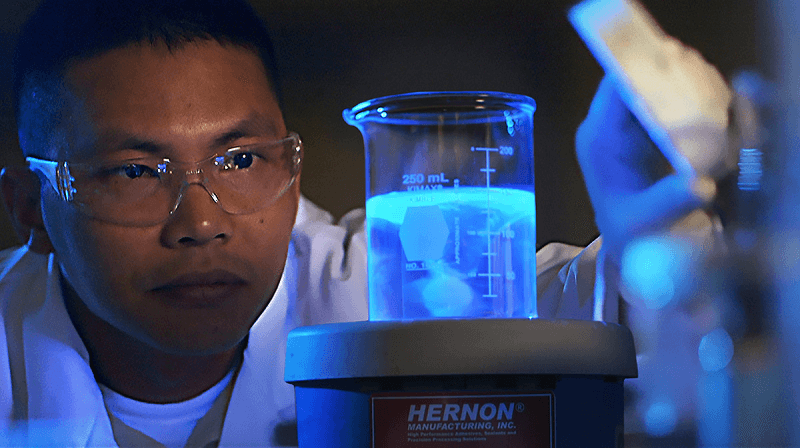

Testing Facilities

Testing

IN DC Engineering organization has world best testing facilities,Statistical process control (SPC) monitors and controls quality by tracking production metrics. It helps quality managers identify and solve problems before products leave the facility. Six Sigma uses five key principles to ensure products meet customers’ needs and have zero defects.When supported by lean tools like Total Productive Maintenance (TPM), 5S, and Kaizen, most if not all defects can be eliminated.

Quality Assurance with Quality Control

Quality assurance streamlines production and helps to ensure that the final products meet the company’s quality criteria. It ensures that the processes used to design, test, and produce products will be done correctly.

In manufacturing, quality assurance approaches, like ISO 9001, help manage and improve many processes, including:

- Acquiring raw materials

- Purchasing third-party components and sub-assemblies

- Designing and using inspection procedures

- Complying with production processes

- Responding to defects

Quality Control, QA and Lean Manufacturing

Lean manufacturing tools can bolster your company’s quality program. Lean revolves around improving quality and safety while increasing efficiency and profits. Some powerful lean manufacturing tools that can bolster your quality system include:

- TPM improves product quality by eliminating downtime, defects, and accidents. TPM accomplishes this through comprehensive maintenance programs and operator training.

- Kaizen helps eliminate problems at their source by empowering workers to find and solve problems on a daily basis.

- 5S helps organize and standardize the workplace. Take control with the 5S System Best Practice Guide, by Graphic Products. Improve procedures and eliminate errors in your facility.

Implement Quality Control in Manufacturing

To implement an effective quality control program, first create and document your approach to quality control. This includes:

- Defining the quality standards for each product

- Selecting the quality control method

- Defining the number of products/batch that will be tested

- Creating and training employees for quality control

- Creating a communication system for reporting defects or potential issues.

Next, you will need to create procedures for handling defects. Consider the following:

- Will batches be rejected if defective items are found?

- Will there be further testing and potential repair work involved?

- Will production be halted to ensure that there are no more defective products created?

- How will new product versions be handled?

Finally, use a method like 5-Whys to identify the root cause of the defect, make any needed changes, and ensure your products are defect free